Health hazards in the Electronics is an issue in occupational hygiene due to the chemical hazard encountered. Health manifestations due to low level exposure to toxins may take decades to surface.

Use of toxic materials such as arsine, phosphine and others potentially expose workers to health hazards which include cancer.

The use of vast variety of toxic chemicals in Electronics makes it difficult to evaluate or pin-point the possibilities of contamination.

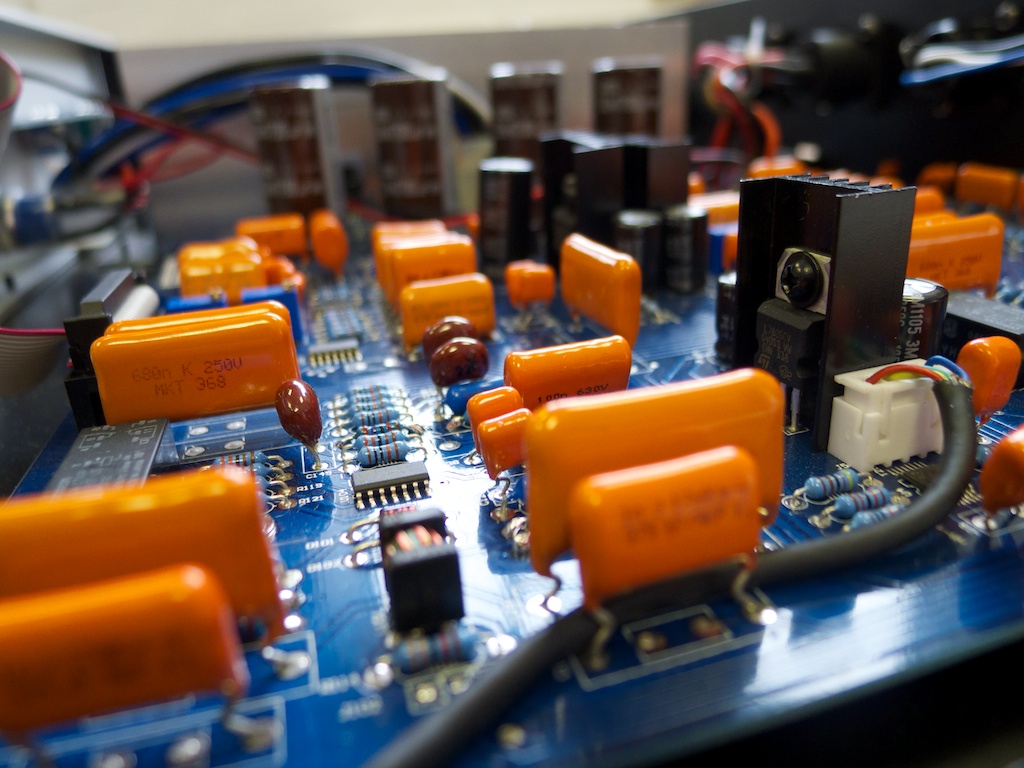

Electronic products such as computers, televisions, lab analyzers, EKG monitors, and other types of biomedical electronic equipment may contain hazardous materials. Of particular concern are heavy metals such as lead (used in cathode ray tube [CRT] monitors and lead solder), mercury (used in the lights behind Liquid Crystal Displays [LCD]), and cadmium (used in batteries, resistors, CRTs, and plastic components), chlorinated plastics (PVC) used in cable wiring, brominated flame retardants (used in plastic computer housing and circuit boards).

PrestiVac vacuum cleaners are equipped with a capacitor to suppress electro-magnetic interference in highly sensitive environments. These vacuums also provide shielding against Radio Frequency Interference (RFI).

Suggested Industrial Vacuums for Recovery of Highly Sensitive Environments

PrestiVac HEPAPlus* Vacuums are specifically designed to safely vacuum toxic dusts. Equipped with a Certified Absolute HEPAPlus*filter with an efficiency of 99.995% on 0.2 micron so there is no risk of exposure or contamination for the operator or the environment. These vacuums are tested for absolute filtration. Testing Method: IEST RP-CC034.3. H14. MIL-STD 282 / A.S.T.M. - D2986-91. MPPS method EN 1822.

PrestiVac cleanroom vacuums are specifically designed to be used in ISO 4 (Class 10) cleanroom/controlled environments for decontamination control. The stainless-steel construction is easy to clean and sterilize. The exhaust air is filtered through a ULPA filtration system with an efficiency of 99.9995% @ 0.12 microns, eliminating the risk of any contamination. Our cleanroom vacuums are grounded and ESD safe so there is no risk of any static build up. Our cleanroom vacuums are also equipped with an electromagnetic (EMI), radio frequency interference (RFI) filter to protect any electronic equipment in the cleanroom.

Which Industries are at Risk with Toxic/Nuisance Dusts created from Electronics?